Procurement Resource, a premier provider of procurement intelligence and market research solutions, is proud to present its latest report on the Neryl Acetate Manufacturing Report. This in-depth and data-driven report is a vital tool for entrepreneurs, manufacturers, and investors aiming to establish or expand their presence in the fragrance and flavor chemicals sector. The document offers exhaustive insights into industry dynamics, manufacturing processes, plant setup requirements, cost structures, and future growth opportunities.

Neryl Acetate: An Essential Ingredient in Fragrance and Flavor Formulations

Neryl Acetate is a naturally occurring ester formed from nerol (a terpene alcohol) and acetic acid, known for its pleasant floral and fruity aroma with hints of lavender and citrus. It has the molecular formula C12H20O2 and plays a critical role in perfumery, cosmetics, and aromatherapy. This compound is also used in flavor formulations for beverages, confectionery, and oral care products.

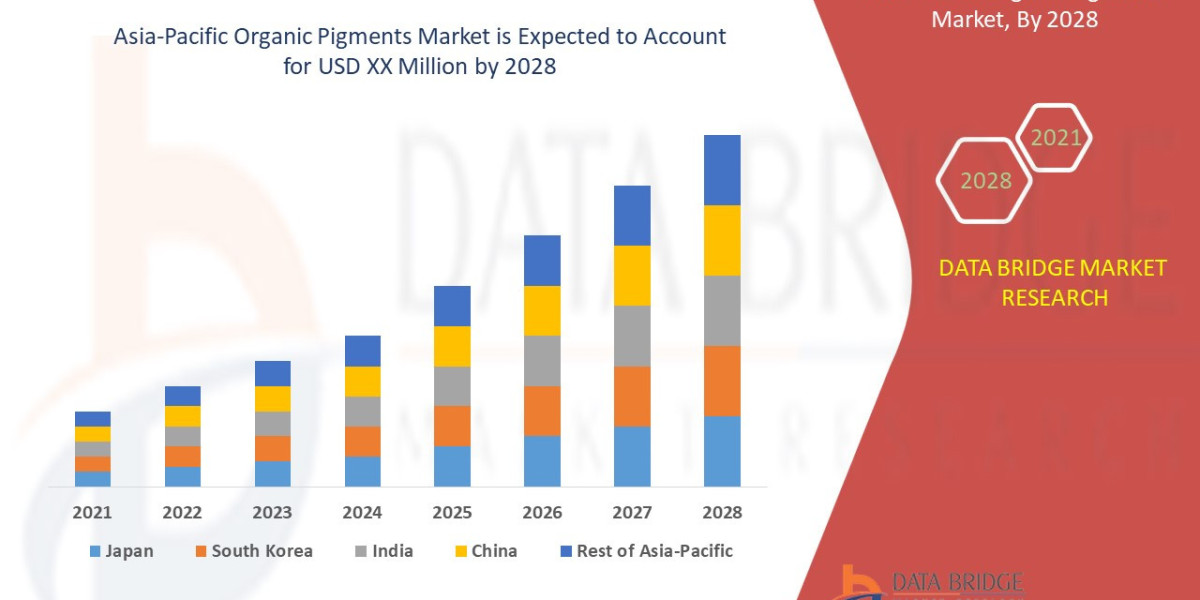

Due to increasing consumer demand for natural and nature-identical fragrance ingredients, Neryl Acetate has become a compound of high industrial relevance. The market for this ester is showing robust growth, particularly in the Asia-Pacific and European regions, driven by expansion in the personal care and wellness industries.

Report Overview: A Complete Guide to Manufacturing Excellence

The Neryl Acetate Manufacturing Plant Report by Procurement Resource offers a 360-degree view of the manufacturing value chain and business setup. From raw materials to finished goods, and from market trends to ROI analysis, the report helps stakeholders make well-informed, strategic decisions.

Key Aspects Covered:

1. Market Overview and Trends

- Industry Demand: The global demand for aroma compounds, including Neryl Acetate, is expanding rapidly due to the popularity of natural and sustainable beauty products.

- End-Use Industries: Key application sectors include cosmetics, personal care, home care, aromatherapy, and food & beverages.

- Geographical Trends: Strong growth is noted in Europe (especially France and Germany) and Asia-Pacific (led by India, China, and Japan), owing to the presence of leading flavor and fragrance manufacturers.

- Pricing Dynamics: The report provides a thorough price trend analysis, comparing historical prices, current benchmarks, and future price forecasts for both raw materials (nerol and acetic acid) and the final product.

2. Manufacturing Process and Technical Insights

Step-by-Step Production Process:

The manufacturing of Neryl Acetate typically involves:

- Esterification Reaction:

- Raw Materials: Nerol and Acetic Acid

- Catalyst: Typically an acid catalyst such as sulfuric acid or p-toluenesulfonic acid

- Reaction Conditions: Controlled temperature and pH levels in a batch or continuous stirred tank reactor (CSTR)

- Distillation & Purification:

- Post-reaction, the crude ester is subjected to fractional distillation to remove unreacted alcohol and acetic acid.

- Final purification ensures high-grade Neryl Acetate suitable for perfumery standards.

Machinery Requirements:

- Reactors (glass-lined or stainless steel)

- Distillation columns

- Condensers and heat exchangers

- Storage tanks

- Quality control lab instruments (GC-MS, HPLC)

Automation Level:

Options include Manual, Semi-Automatic, and Fully Automatic setups depending on investment capacity and production volume.

3. Infrastructure and Utility Requirements

Establishing a Neryl Acetate manufacturing unit requires:

- Land and Building: Industrial land with proper zoning, preferably in a chemical manufacturing cluster

- Water and Power Supply: Essential for reaction control and cooling processes

- Effluent Treatment Plant (ETP): To comply with environmental regulations

- Manpower: Skilled chemical engineers, plant operators, and QC personnel

4. Quality Standards and Regulatory Compliance

- International Fragrance Association (IFRA) guidelines must be adhered to, especially for use in cosmetics and perfumery.

- Compliances include REACH (EU), FDA (USA) (for food-grade usage), and BIS (India).

- Testing protocols include gas chromatography, mass spectrometry, and sensory evaluation.

5. Economic Analysis and Financial Forecasting

Capital Investment Breakdown:

- Plant & Machinery: 35–40% of total investment

- Land & Infrastructure: 20–25%

- Working Capital: 20%

- Miscellaneous and Contingencies: 10–15%

Operating Costs:

- Raw Materials: Largest component (nerol is cost-sensitive due to supply chain fluctuations)

- Labor, Utilities, Maintenance

- Waste Management and Safety

Profit Projections & ROI:

- Breakeven Point: Typically achievable within 3–5 years, depending on scale and operational efficiency.

- Gross Margins: High, particularly for export-quality or natural-origin certified products.

- Export Potential: Strong, especially in Europe and North America, where natural fragrance ingredients are in high demand.

Sustainability & Innovation in Manufacturing

With a shift towards green chemistry and biologically derived ingredients, modern Neryl Acetate manufacturing plants are exploring:

- Bio-based synthesis routes using renewable feedstocks

- Energy-efficient processes through waste heat recovery and process optimization

- Zero Liquid Discharge (ZLD) technologies for environmental compliance

- Integration of AI and data analytics for real-time process monitoring and yield optimization

Companies are also investing in R&D to produce high-purity isomers and reduce byproduct generation, thus improving process economics and environmental footprint.

Why Choose Procurement Resource?

Procurement Resource is a trusted name in the field of cost modeling, procurement benchmarking, market intelligence, and strategic advisory for chemical and manufacturing industries. Our reports are developed by expert researchers, chemical engineers, and data scientists with deep domain knowledge.

Key Advantages:

- Tailored insights based on project scale and geography

- Detailed cost structure analysis for raw materials, energy, labor, and logistics

- Global pricing databases and procurement trends

- Strategic planning support for financing, supply chain setup, and regulatory navigation

Get a Free Sample Report

Businesses, entrepreneurs, and consultants looking to invest in or understand the Neryl Acetate production business can request a free sample report from Procurement Resource. The sample includes a brief market overview, production process outline, and preliminary cost estimations.

Request your sample here: https://www.procurementresource.com/reports/neryl-acetate-manufacturing-plant-project-report/request-sample

Contact Information

Company Name: Procurement Resource

Contact Person: Ashish Sharma (Sales Representative)

Email: [email protected]

Location: 30 North Gould Street, Sheridan, WY 82801, USA

Phone:

UK: +44 7537171117

USA: +1 307 363 1045

APAC: +91 1203185500

Connect With Us Online:

https://www.linkedin.com/company/procurement-resource-official/